Understanding Pyrolysis Equipment

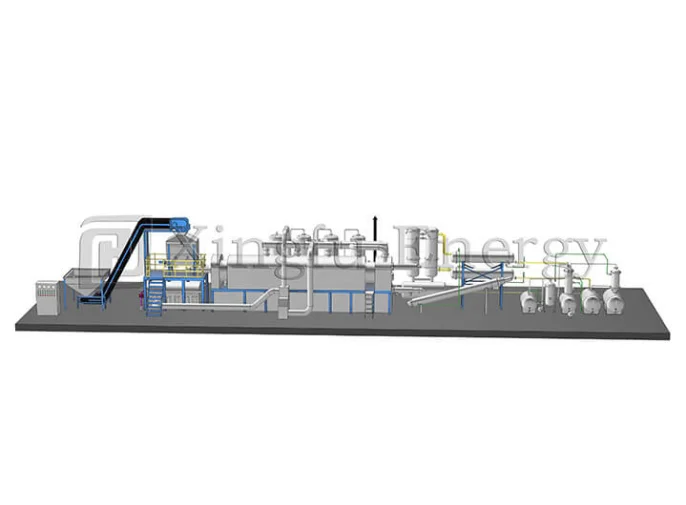

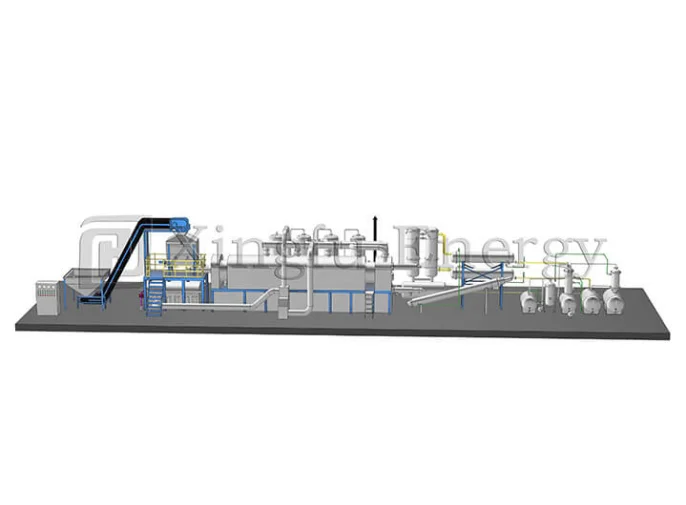

Overview of Pyrolysis Machines

Pyrolysis machines are key tools. Qingdao Xingfu Energy Equipment Co.,Ltd produces various types of pyrolyzers, they transform waste, like plastics and tires, into useful products. These include fuel oil, carbon black, and syngas. The process, called pyrolysis, breaks down organic materials with heat. It happens without oxygen. This green technology cuts waste. It also offers a new energy source.

Types of Pyrolysis Equipment and Their Applications

Pyrolysis equipment varies by design and use. There are fully automatic plastic pyrolysis and semi-automatic plastic pyrolysis plants. Fully automatic plastic pyrolysis machines work efficiently. They need little human effort. Semi-automatic ones cost less. But they require more labor. Waste tire pyrolysis machines also differ. Whole tire pyrolysis plants handle uncut tires. Broken tire systems speed up heating. They reduce heat loss. Each type meets specific needs.

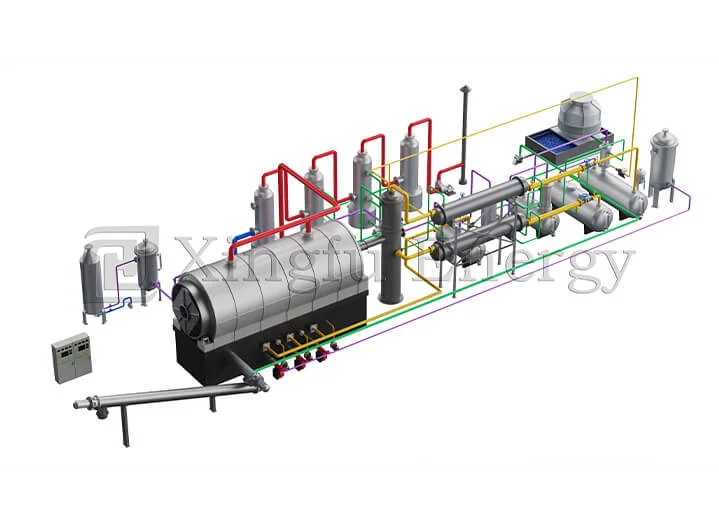

Key Components of a Plastic Pyrolysis Machine

A typical plastic pyrolysis machine has vital parts:

- Reactor: The main area for thermal breakdown.

- Cooling System: Turns vapors into liquid fuel.

- Oil Separator: Removes impurities from oil.

- Dust Removal System: Cuts emissions during operation.

- Control Panel: Lets operators adjust settings for best results.

These parts ensure efficiency. They also meet environmental rules.

Importance of Regular Maintenance for Pyrolysis Machines

Benefits of Proper Maintenance Practices

Regular care keeps pyrolysis machines running well. It extends their life. Well-kept equipment gives steady output quality. It lowers running costs. It also cuts downtime. Routine checks spot issues early. This avoids pricey fixes. For companies using pyrolysis technology, this boosts profits. It supports green operations.

Risks of Neglecting Maintenance in Pyrolysis Equipment

Ignoring upkeep has big downsides. Wear can harm key parts, like reactors or cooling systems. This hurts output quality. It raises energy use. In bad cases, neglect causes machine failure. It can also create safety risks, like overheating or pressure buildup.

Routine Maintenance Procedures for Pyrolysis Machines

Inspection and Cleaning of Core Components

Regular checks are crucial. They find wear or damage in parts like reactors, pipes, and separators. Cleaning these areas stops residue clogs. For example:

- Look at reactors for cracks.

- Clear cooling pipes for good heat flow.

- Check oil separators for blockages.

Proper cleaning boosts performance. It also lengthens equipment life.

Lubrication Requirements for Moving Parts

Moving parts need care. Conveyor belts and rotary systems require lubrication. This reduces friction. It prevents wear. High-quality lubricants keep things smooth. They cut energy loss. Follow the maker’s advice on lubrication timing and types.

Monitoring Control Systems and Sensors

Modern pyrolysis machines have smart controls. Sensors manage temperature and pressure. Routine calibration keeps them accurate. Faulty sensors give wrong data. This can disrupt work. It may also risk safety. Qingdao Xingfu Energy Equipment Co., Ltd., based in Qingdao since 2010, makes industrial boilers and waste systems like plastic pyrolysis machines tailored to needs.

Preventive Measures to Enhance Equipment Longevity

Identifying Early Signs of Wear and Tear

Spotting wear early is vital for a pyrolysis machine’s efficiency. Check key parts often. These include the reactor, cooling system, and oil separator. Look for cracks or odd sounds during use. A faulty cooling system may lower fuel oil output. Fixing issues fast prevents bigger problems. It keeps performance steady.

Scheduling Regular Technical Inspections

Technical checkups find hidden flaws. Routine checks may miss these. Hire skilled technicians to review the machine’s state. They can spot issues in sensors or pipes. Inspections ensure all parts work well. They lower the chance of sudden breakdowns. Stick to the maker’s inspection schedule for reliability.

Ensuring Proper Installation and Usage

Correct setup aids long-term performance. Install the plastic pyrolysis machine on a firm base. This stops vibrations that harm parts. Follow the maker’s usage rules. Avoid overloading the machine. Don’t exceed its limits. For example, wet feedstock strains the reactor. It slows pyrolysis.

Troubleshooting Common Issues in Plastic Pyrolysis Machines

Addressing Temperature Fluctuations

Temperature swings hurt output quality. They affect efficiency in a plastic pyrolysis machine. Low temperatures cause incomplete breakdown. This cuts fuel oil yields. High temperatures risk safety. They may damage reactor linings. Calibrate sensors often. Monitor controls to keep conditions stable.

Managing Blockages in the Feedstock System

Feedstock blockages disrupt work. Residue or poor material prep often causes them. Clean feeding systems regularly. Shred materials well before loading. This prevents clogs. It also improves heat spread in the reactor.

Resolving Oil Leakage Problems

Oil leaks are common in pyrolysis machines. Worn seals or loose pipe fittings cause them. Check these areas during upkeep. Replace bad seals quickly. Use strong gaskets and fittings. This reduces leak risks.

Best Practices for Long-Term Efficiency of Pyrolysis Equipment

Training Operators on Proper Usage and Maintenance

Training operators is key. It ensures correct use of pyrolysis machines. Skilled workers follow best practices. They stick to operating limits. They handle routine care well. Training should cover fixing issues, using controls, and spotting wear signs.

Keeping Accurate Records of Maintenance Activities

Detailed upkeep records track performance. They show recurring problems or part failures. This helps plan preventive steps. Logs ensure warranty compliance. They aid decisions on upgrades or replacements.

Upgrading Components to Improve Performance

Upgrades boost a plastic pyrolysis machine’s efficiency. Better cooling systems raise fuel oil yields. They improve vapor condensation. Modern control panels offer precise monitoring. They allow fine-tuned settings. Qingdao Xingfu Energy Equipment Co., Ltd., based in Qingdao since 2010, makes industrial boilers and waste systems like plastic pyrolysis machines tailored to needs. And they have the technology and equipment certified by professional organizations to provide you with unparalleled service.

Frequently Asked Questions

What are some preventive measures to extend the lifespan of a pyrolysis machine?

Spot wear early. Schedule regular checkups. Install equipment correctly. Follow operating guidelines.

How can temperature fluctuations affect a plastic pyrolysis machine?

Swings cause incomplete breakdown or overheating. They hurt output quality. They may damage parts like reactors.

What should operators do if they encounter blockages in the feedstock system?

Clean feeding systems often. Shred feedstock well before loading. This stops clogs.

Why is operator training important for maintaining pyrolysis equipment?

Training teaches best practices. It cuts downtime from mishandling or neglect.

Readers interested in learning more about advanced solutions offered by Qingdao Xingfu Energy Equipment Co.,Ltd can contact their team directly through their provided communication channels for further assistance!

MORE