012025/04

Introduction to Pyrolysis as a Solution

What is Pyrolysis?

Pyrolysis is a heat-driven process that breaks down organic matter at high temperatures without oxygen. It works well for handling plastic waste. The method turns plastics into useful items like fuel oil, gas, and char. Plastic pyrolysis is growing popular. It’s a fresh way to tackle the increasing problem of plastic buildup.

272025/03

Understanding the Pyrolysis Process

Definition and Mechanism

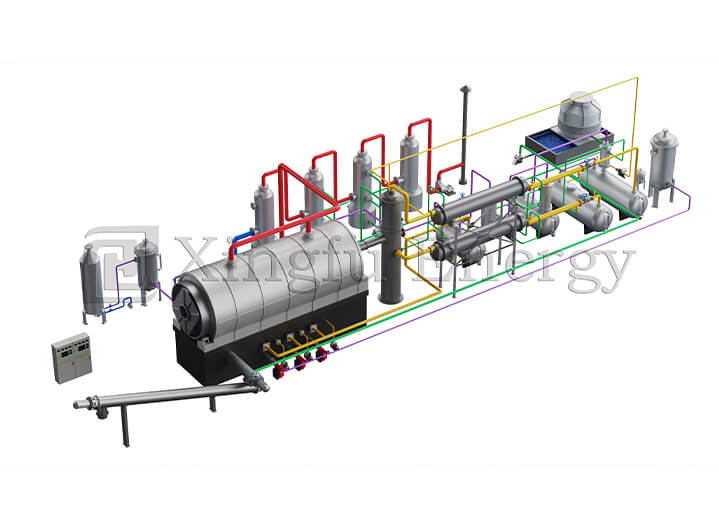

Pyrolysis is a heat-based breakdown process. It happens without oxygen. This method splits organic substances into simpler parts. It works by warming the material to high temperatures. As a result, it releases gaseous elements and leaves a solid remainder. This technique is vital for turning waste into useful items. Examples include fuel oil, carbon black, and syngas.

Types of Pyrolysis

Several kinds of pyrolysis exist. Each has unique features and uses. These include slow, fast, and flash pyrolysis. Slow pyrolysis uses lower heat and longer durations. It produces more char. Fast pyrolysis employs moderate heat and brief periods. It boosts liquid output. Flash pyrolysis uses very high heat for extremely short times. It mainly creates gases.

Key Parameters in Pyrolysis

The success of pyrolysis relies on certain factors. These include temperature, heating speed, duration, and material makeup. Remark: This factor is just for reference. Size changes due to design upgrades won’t be specially announced to customers. Please check documents included with products. These elements affect the mix of outputs like oil, gas, and char.

Pyrolysis of Plastic Waste

Challenges in Plastic Waste Management

Handling plastic waste is tough. It doesn’t break down naturally. Common methods like landfilling and burning harm the environment. They release pollution and greenhouse gases. Thus, new approaches like pyrolysis provide a green option. It transforms plastic waste into reusable materials.

Conversion of Plastics to Fuels and Chemicals

Pyrolysis of plastic waste breaks polymers into smaller units. These units are hydrocarbons. They can be processed into fuels and chemicals. Product Recovery Rate: Fuel oil: 60-85%, Carbon black: 10-30%, Syn gas: 5-10%. This reduces plastic waste volume. It also offers another energy source.

Environmental Impact and Benefits

Plastic pyrolysis has green advantages. It cuts landfill use. It reduces dependence on fossil fuels. It lowers carbon emissions too. Plus, it recovers resources from waste. The process aligns with circular economy ideas. It turns waste into valuable goods.

Tyre Pyrolysis Applications

Recycling of End-of-Life Tyres

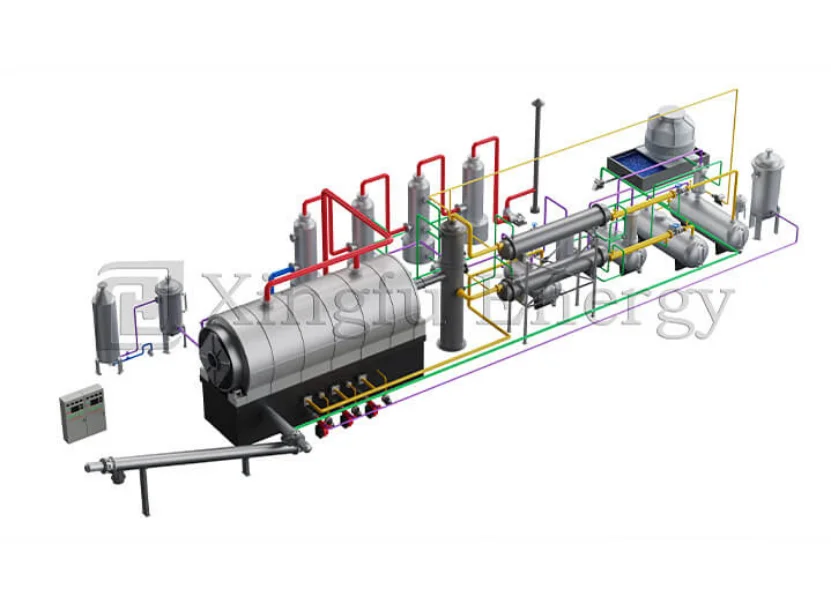

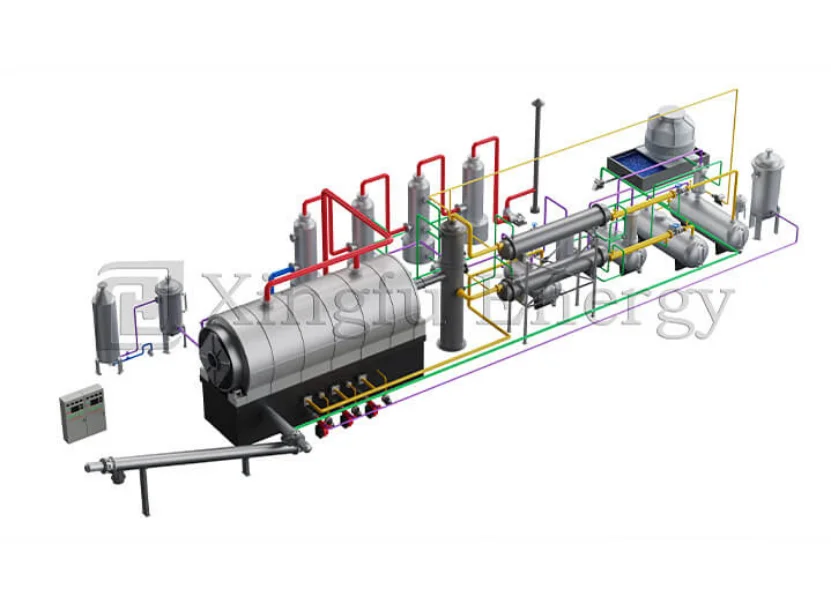

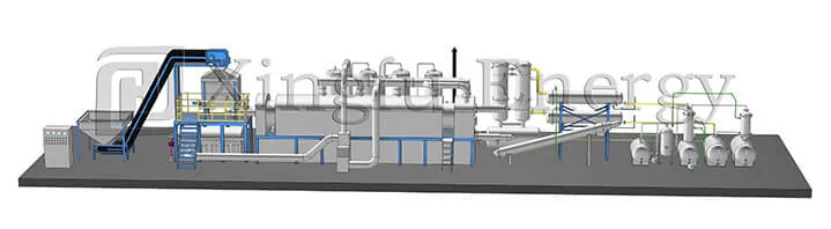

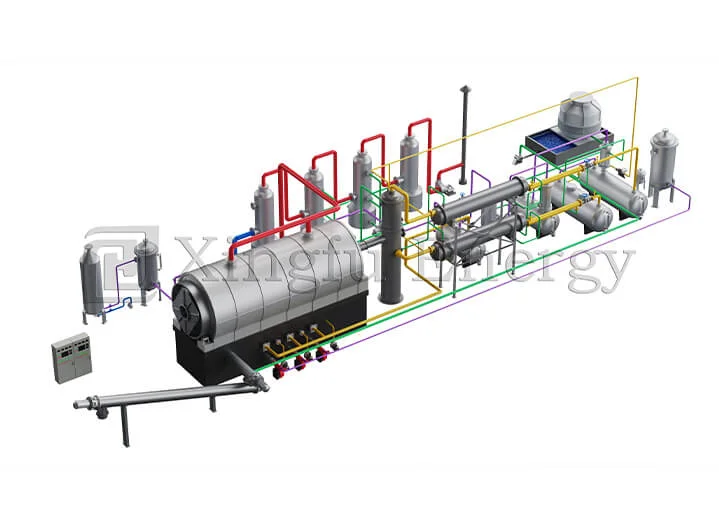

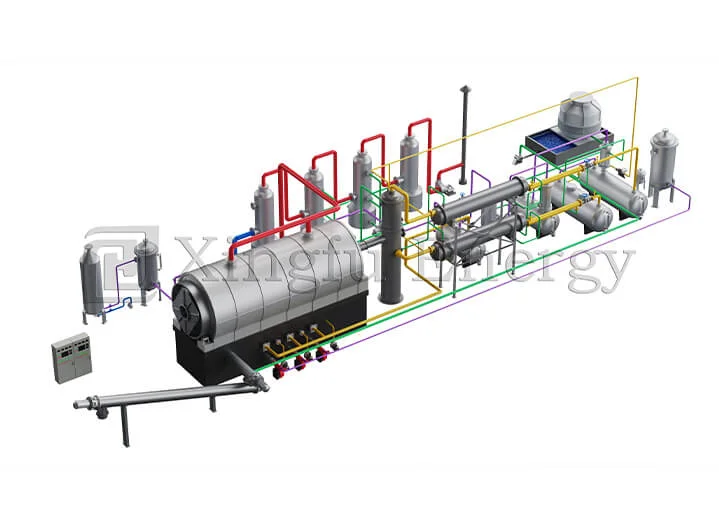

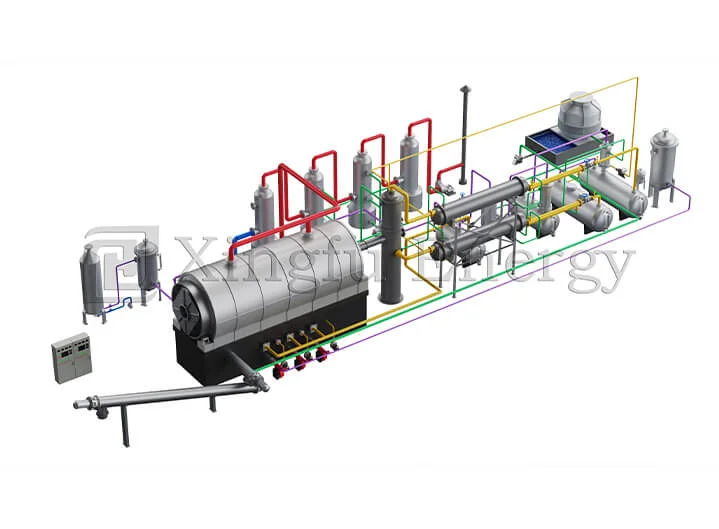

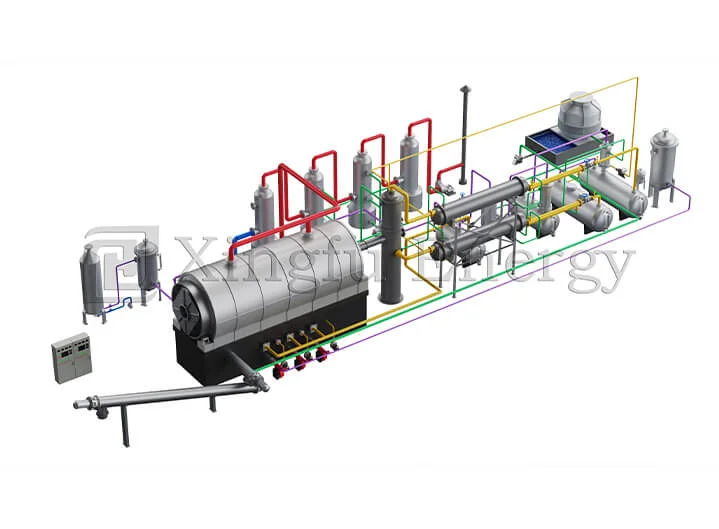

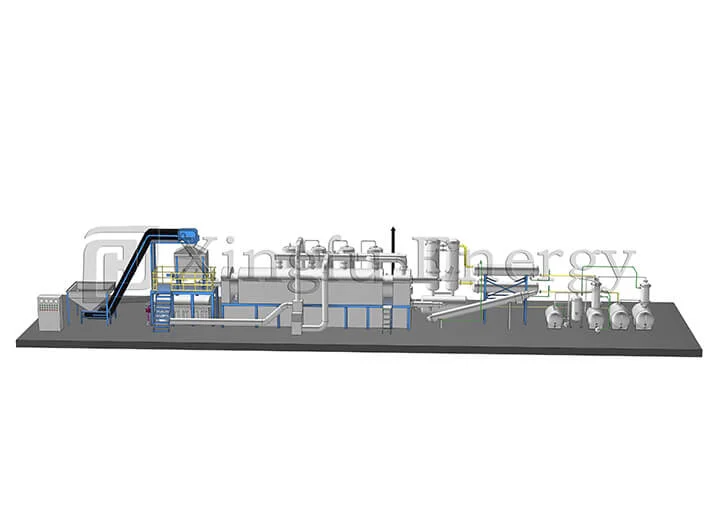

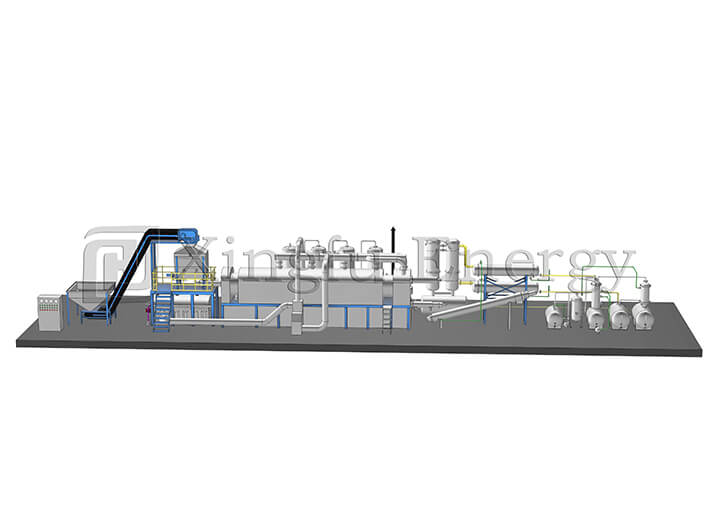

Old tyres are hard to dispose of. They’re tough and bulky. Tyre pyrolysis offers a solid recycling fix. It converts tyres into useful items. These include fuel oil, carbon black, and steel wire. Whole tyre feed, no need to cut; reduced the cost. It uses multilevel cooling circulation. This increases fuel oil yield. Pulse dust removal during discharge ensures no dust. It’s easy to run and efficient. Only 2-3 workers are needed. Qingdao Xingfu Energy Equipment Co.,Ltd adopts fully automatic submerged arc welding and x-ray checks. This boosts plant safety.

252025/03

Understanding Pyrolysis Processes

The Basics of Pyrolysis

Pyrolysis is a heat-based breakdown method. It happens at high temperatures without oxygen. This approach transforms waste into useful materials. Pyrolysis Plant,Oil Distillation Equipment Manufacturer, a professional maker of pyrolysis and distillation tools, highlights its value. By decomposing complex items like tyres and plastics, it yields products such as oil, gas, and char.

202025/03

Pyrolysis technology is the cutting-edge waste treatment and recovery technology with focus towards waste conversion into useful resources.

Like with any other bit of sophisticated industrial equipment, the long-term profitability, safety, and efficiency of a pyrolysis plant all depend heavily on preventive and careful maintenance.

So, in 2025 and beyond, what are the most critical steps and precautions that need to be followed for optimal pyrolysis equipment performance?

Pyrolysis technology is the cutting-edge waste treatment and recovery technology with focus towards waste conversion into useful resources.

Like with any other bit of sophisticated industrial equipment, the long-term profitability, safety, and efficiency of a pyrolysis plant all depend heavily on preventive and careful maintenance.

So, in 2025 and beyond, what are the most critical steps and precautions that need to be followed for optimal pyrolysis equipment performance?

182025/03

Waste management is a critical problem in the contemporary world. From trash-filled dump sites to industrial and plastic wastes, the times need drastic action more than anything else. But imagine if instead of exporting waste for dumping, it could be used to import precious items. That is where pyrolysis plants can prove to be useful.

Pyrolysis is a highly advanced thermal decomposition process that assists in the conversion of waste material into high-value products such as fuel oil, syngas, and carbon black.

Now, what is a pyrolysis plant, and how does a pyrolysis plant work? Let us discuss the process, the feedstock which can be processed, and advantages it has to offer a greener future.

Waste management is a critical problem in the contemporary world. From trash-filled dump sites to industrial and plastic wastes, the times need drastic action more than anything else. But imagine if instead of exporting waste for dumping, it could be used to import precious items. That is where pyrolysis plants can prove to be useful.

Pyrolysis is a highly advanced thermal decomposition process that assists in the conversion of waste material into high-value products such as fuel oil, syngas, and carbon black.

Now, what is a pyrolysis plant, and how does a pyrolysis plant work? Let us discuss the process, the feedstock which can be processed, and advantages it has to offer a greener future.