Pyrolysis is a heat-based breakdown method. It happens at high temperatures without oxygen. This approach transforms waste into useful materials. Pyrolysis Plant,Oil Distillation Equipment Manufacturer, a professional maker of pyrolysis and distillation tools, highlights its value. By decomposing complex items like tyres and plastics, it yields products such as oil, gas, and char.

The key distinction between tyre pyrolysis and plastic pyrolysis is the input. Tyre pyrolysis breaks down used tyres. These contain rubber, steel wire, and other substances. Plastic pyrolysis, however, processes waste plastics. Their makeup differs based on types like polyethylene or polypropylene.

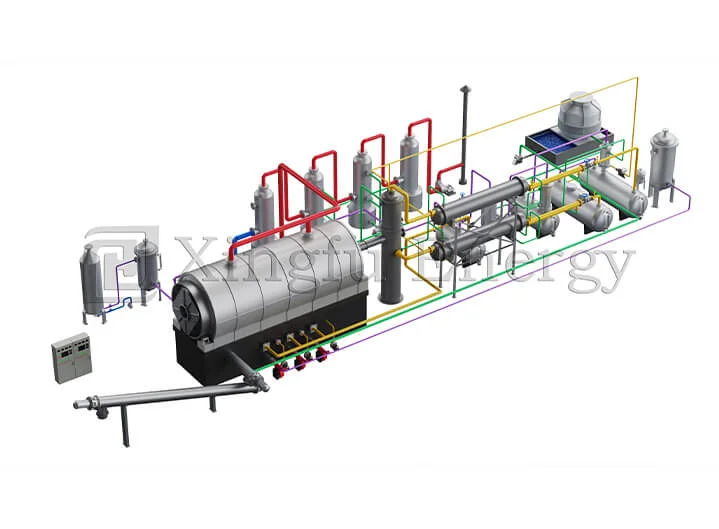

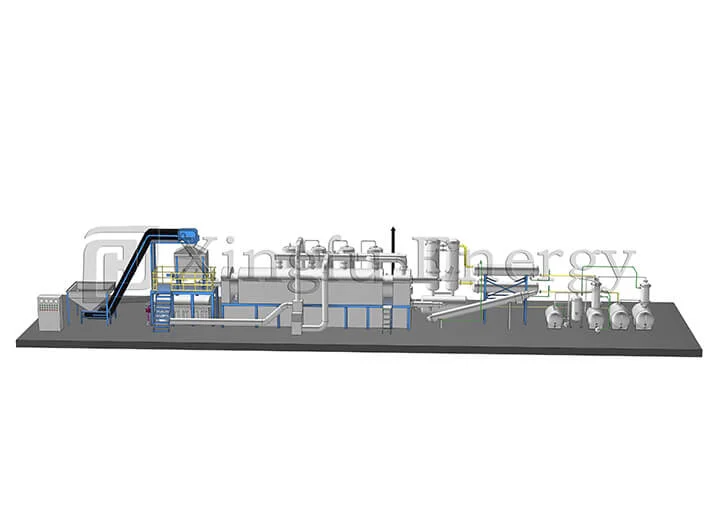

Both tyre and plastic pyrolysis need high heat. They also require an oxygen-free setting to avoid burning. Airtight high temperature feed saves heating time. It also cuts heat loss. This setup ensures materials split into simpler parts instead of combusting.

Tyre pyrolysis oil is a blend of hydrocarbons from rubber breakdown. It often has aromatic compounds. These give it unique chemical traits. The oil can serve as fuel or be refined into higher-value goods.

Plastic pyrolysis oil depends on the plastic type. It usually has aliphatic hydrocarbons. These have fewer aromatic compounds than tyre oil. Fuel oil:60-85% shows plastic oil offers a higher output potential. This is due to plastics’ simpler structure.

Density and viscosity affect how pyrolysis oils work as fuels. Tyre oils tend to be denser. This comes from heavier aromatic compounds. Plastic oils are typically lighter and less thick. That makes them simpler to use in fuel systems.

Residue levels matter when comparing these oils. Tyre pyrolysis leaves more residue. Steel wire and non-burnable parts in tyres cause this. Steel wire:14-16% points to that fact. Plastic oils often have less residue. Plastics lack metal components.

The heating value of tyre oil ties to its aromatic content. This boosts its energy strength. It fits well as an industrial fuel. It can also be refined into diesel-like products.

Plastic oils usually have a lower heating value. Their aliphatic makeup explains this. Still, they provide notable energy potential. They work as alternative fuels or raw materials for chemical uses.

Qingdao Xingfu Energy Equipment Co.,Ltd offers tailored services for those keen to explore these methods.

Tyre pyrolysis oil suits industrial needs. Its high aromatic content helps. It powers diesel engines with high strength and low speed. It also fuels heating furnaces and metalwork processes. Refining it into diesel-grade items adds to its worth in energy-heavy fields.

Plastic pyrolysis oil comes from various waste plastics. It has strong potential as an energy source. Fuel oil:60-85% shows its high yield. This makes it great for industrial boilers and power stations. Its aliphatic nature also suits it for chemical production. This flexibility reduces dependence on traditional fossil fuels.

Tyre pyrolysis impacts the environment through emissions. It’s greener than burning waste outright. Yet, it still releases some pollutants. Tools like pulse dust removal during discharge process cut dust. This improves air quality. Managing emissions well keeps tyre pyrolysis sustainable.

Plastic pyrolysis helps manage plastic waste. It turns non-degradable items into resources. This cuts landfill use. Still, it produces emissions too. These need control to limit harm. Advanced emission tools can shrink its environmental mark.

The profitability of tyre and plastic pyrolysis depends on factors. Market need for by-products is one. Operating costs matter too. Tyre products like steel wire:14-16% add income via recycling. Plastic pyrolysis benefits from high oil yields and versatility. But oil price swings and rules can affect earnings.

New tech boosts pyrolysis efficiency and safety. Fully automatic submerged arc welding strengthens plant safety. Better cooling and heat reuse systems also help. They lower costs and raise oil recovery. These advances open doors for wider use of pyrolysis worldwide.

Qingdao Xingfu Energy Equipment Co.,Ltd provides custom solutions for those interested in these technologies.

The key lies in the materials. Tyre pyrolysis uses waste tyres. Plastic pyrolysis uses waste plastics.

Tyre oils have more aromatic hydrocarbons. Plastic oils contain more aliphatic compounds.

Steel wire and non-burnable parts in tyres increase residue during pyrolysis.

Yes, both serve as alternative fuels. Their energy potentials differ though.

They offer custom pyrolysis plant setups to meet specific needs.

For more details or questions about Qingdao Xingfu Energy Equipment Co.,Ltd’s services, contact them directly via their official channels.