Waste management is a critical problem in the contemporary world. From trash-filled dump sites to industrial and plastic wastes, the times need drastic action more than anything else. But imagine if instead of exporting waste for dumping, it could be used to import precious items. That is where pyrolysis plants can prove to be useful.

Pyrolysis is a highly advanced thermal decomposition process that assists in the conversion of waste material into high-value products such as fuel oil, syngas, and carbon black.

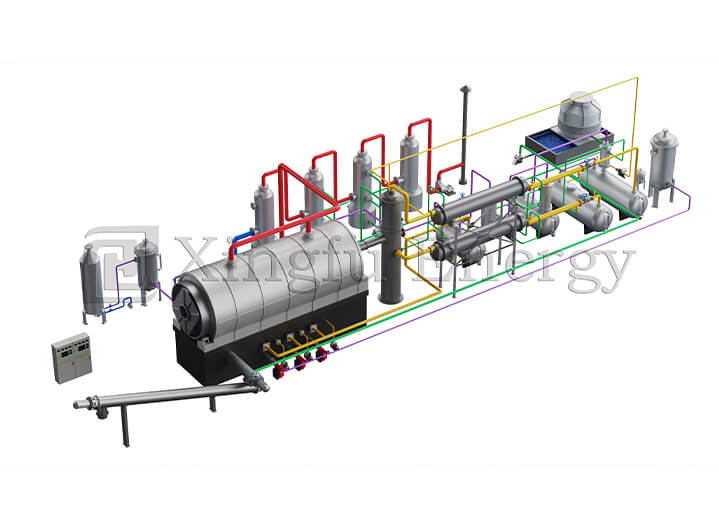

Now, what is a pyrolysis plant, and how does a pyrolysis plant work? Let us discuss the process, the feedstock which can be processed, and advantages it has to offer a greener future.

A pyrolysis plant is governed by the principle of thermal decomposition. Pyrolysis refers to the thermal decomposition of organic waste in the absence of oxygen.

Pyrolysis differs from combustion, in which waste material is combusted in the presence of oxygen to form combustion products.

Pyrolysis is employed to destroy chemical bonds in the product and form useful byproducts.

1. Raw Material Feeding:Raw material such as plastics, tyres, biomass or oil sludge is supplied. Large setups utilize automated feeders for ease.

2. Pyrolysis Reaction:The feedstock is supplied to the pyrolysis reactor where it’s heated from 300°C to 450°C.

Product Separation: By-product of waste decomposition is given as:

1. Pyrolysis Oil: Results due to condensation reaction

2. Syngas: Compressible gas that can be reused for producing heat

3. Carbon Black or Biochar:A solid by-product of useful application in industries

4. Treatment and Control of Gas Emission:New pyrolysis units to prevent pollution purify and filter the exhaust before emission. Syngas is utilized for different purposes in auto-catalytic processes by some installations.

5. Storage and Collection:Products are stored and collected and then re-sold or re-processed.

Yes, pyrolysis effectively recycles plastic waste into syngas and pyrolysis oil. It will not contaminate plastic and is a great substitute for conventional fossil fuels.

Waste tires consist of rubber, steel, and fiber. Pyrolysis yields high-quality fuel oil, carbon black, and steel wire, thereby making tire waste profitable and simple to dispose of.

Pyrolysis of oil sludge refers to an operation of treatment of oil sludge by drilling and hydrocarbon treatment. Pyrolysis units stabilize hazardous residue and obtain utilisable oil from the sludge, with destruction of environment risk.

Actually, biomass including wood chips, agricultural wastes, and sawdust are good enough to use pyrolysis in order to produce biochar, syngas, and bio-oil, all being applied for renewable energy.

Pyrolysis oil is industrial burner fuel, generator fuel, and further refining to diesel.

Syngas, mostly hydrogen and carbon monoxide, can be employed for electricity, heat, or used as synthetic fuel feedstock.

Carbon black is solid industrial residue that finds widespread applications in rubber production, ink, and UV stabilizing plastics.

Steel wire is recovered in tire pyrolysis, which can be recycled and melted for steel production, thus conserving raw materials.

Pyrolysis also conserves waste from landfills, is free from contamination, and facilitates circular economy through recycling of waste material.

Pyrolysis equipment induces energy independence since it consumes less fossil fuel as the waste is removed and turned into gas and fuel.

1. Averts Greenhouse Gases: While landfilling will see the emission of methane gas, pyrolysis seizes control over methane gas.

2. Reduces Groundwater Contamination:It is a dry process, thus avoiding the risk of chemicals leaching.

3. Cures Compounds Pesticide-Poisoning:The majority of toxic compounds are killed by heat.

Pyrolysis plants can earn revenues from fuel oil, syngas, and byproduct sales. Pyrolysis plants also create jobs in waste management.

Pyrolysis technology is capable enough to be utilized on various waste streams and plant capacities and hence is most suitable for implementation in small industry and large industry.

The searchers of reliable good quality pyrolysis solution can rely on Qingdao Xingfu Energy Equipment CO.,LTD. as a reliable firm. The firm, since its establishment in the year 2010, is involved in waste tire & plastic, biomass, oil sludge pyrolysis plants and provides batch-type, semi-continuous, and fully continuous pyrolysis plants for sale.

Pyrolysis technology is effective, green, and lucrative to apply in waste management. It converts waste into energy and useful material and minimizes its environmental impact and promotes economic growth.

With each passing day, technology is advancing, and pyrolysis can be at the forefront of sustainable energy, circular economy technologies, and global sustainability. Whatever industrial, municipal, or individual scale it may be, pyrolysis technologies can lead the way to a cleaner, resource-efficient future.