Pyrolysis is a heat-based breakdown process. It happens without oxygen. This method splits organic substances into simpler parts. It works by warming the material to high temperatures. As a result, it releases gaseous elements and leaves a solid remainder. This technique is vital for turning waste into useful items. Examples include fuel oil, carbon black, and syngas.

Several kinds of pyrolysis exist. Each has unique features and uses. These include slow, fast, and flash pyrolysis. Slow pyrolysis uses lower heat and longer durations. It produces more char. Fast pyrolysis employs moderate heat and brief periods. It boosts liquid output. Flash pyrolysis uses very high heat for extremely short times. It mainly creates gases.

The success of pyrolysis relies on certain factors. These include temperature, heating speed, duration, and material makeup. Remark: This factor is just for reference. Size changes due to design upgrades won’t be specially announced to customers. Please check documents included with products. These elements affect the mix of outputs like oil, gas, and char.

Handling plastic waste is tough. It doesn’t break down naturally. Common methods like landfilling and burning harm the environment. They release pollution and greenhouse gases. Thus, new approaches like pyrolysis provide a green option. It transforms plastic waste into reusable materials.

Pyrolysis of plastic waste breaks polymers into smaller units. These units are hydrocarbons. They can be processed into fuels and chemicals. Product Recovery Rate: Fuel oil: 60-85%, Carbon black: 10-30%, Syn gas: 5-10%. This reduces plastic waste volume. It also offers another energy source.

Plastic pyrolysis has green advantages. It cuts landfill use. It reduces dependence on fossil fuels. It lowers carbon emissions too. Plus, it recovers resources from waste. The process aligns with circular economy ideas. It turns waste into valuable goods.

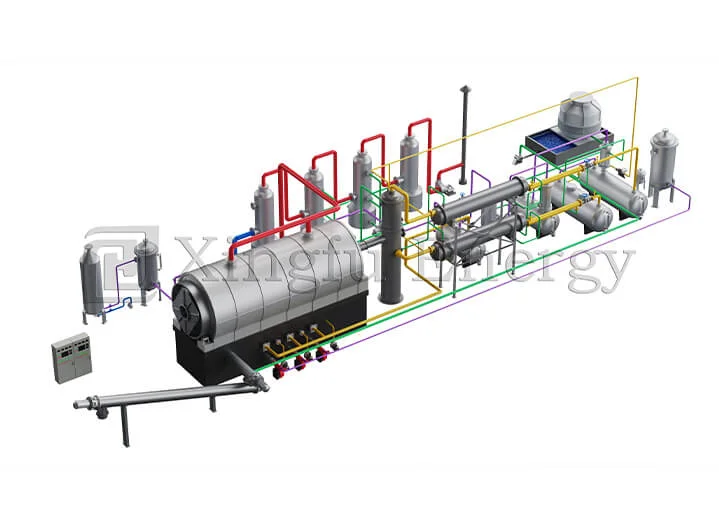

Old tyres are hard to dispose of. They’re tough and bulky. Tyre pyrolysis offers a solid recycling fix. It converts tyres into useful items. These include fuel oil, carbon black, and steel wire. Whole tyre feed, no need to cut; reduced the cost. It uses multilevel cooling circulation. This increases fuel oil yield. Pulse dust removal during discharge ensures no dust. It’s easy to run and efficient. Only 2-3 workers are needed. Qingdao Xingfu Energy Equipment Co.,Ltd adopts fully automatic submerged arc welding and x-ray checks. This boosts plant safety.

Tyre pyrolysis yields key products. Pyrolytic oil serves as industrial fuel or can be refined into diesel. Carbon black is used in production. Steel wire is reused in various ways. Product Recovery Rate: Oil: 40-45%, Carbon black: 32-36%, Steel wire: 14-16%, Syn gas: 5-8%.

Tyre pyrolysis is cost-effective. It supplies affordable raw materials to industries. It also tackles tyre disposal issues. The products serve many purposes, from energy to manufacturing. Qingdao Xingfu Energy Equipment Co.,Ltd provides tailored services for renewable energy equipment needs.

Catalysts improve pyrolysis results. They reduce the energy needed to break down materials. This leads to better conversion rates and product quality. Researchers keep testing new catalyst types. They aim to perfect pyrolysis for plastics and tyres. These improvements raise profits. They also enhance green benefits by maximizing resource use.

New reactor designs boost pyrolysis efficiency. They ensure even heat spread. They cut energy use too. They improve product recovery rates. For example, Qingdao Xingfu Energy Equipment Co.,Ltd uses fully automatic submerged arc welding and x-ray checks. This raises safety levels. Multilevel cooling systems increase fuel oil output in tyre pyrolysis. These upgrades make pyrolysis fit well into waste management setups.

Fine-tuning conditions is key in pyrolysis. Temperature, pressure, and duration are controlled carefully. These affect product types and quality. Advanced systems monitor and adjust in real time. This ensures top performance with different materials. Operators can tweak the process to meet specific goals. This lifts both efficiency and earnings.

Pyrolysis fits well into circular economy plans. It turns waste into useful resources. By converting plastics into fuels and chemicals, it supports sustainable ideas. This tackles environmental woes. It also opens economic doors through green resource use. As industries adopt circular habits, pyrolysis will help meet sustainability targets.

Expanding pyrolysis worldwide has pros and cons. Better reactors and catalysts aid growth. But rules, market needs, and infrastructure matter too. Governments, companies, and researchers must work together. This will push pyrolysis adoption globally.

Pyrolysis has critics due to possible emissions. To fix this, emission controls must improve. For instance, pulse dust removal cuts dust during discharge. Clear reports on green performance can build trust. They show the industry’s focus on clean practices.

Its key benefit is turning waste into useful items like fuel oil and chemicals. It also reduces environmental harm.

It recycles old tyres well. It transforms them into oil, carbon black, and steel wire.

It cuts landfill use. It lowers carbon emissions. It provides energy from waste plastics too.

Most plastics can be used. Mixed plastics often work better due to varied hydrocarbon content.

For more details on tailored solutions for your renewable energy needs or questions about Qingdao Xingfu Energy Equipment Co.,Ltd’s services, feel free to reach out or check our offerings!