The worldwide push for greener energy has greatly boosted the use of pyrolysis oil as a nature-friendly choice. This oil comes from waste stuff like old tires and plastics. It burns cleaner than old-school fossil fuels. Factories are keen to cut their carbon mark. Pyrolysis oil fits this goal well by using waste that’d otherwise dirty the planet. The fuel oil from pyrolysis can run diesel engines, heat ovens, metal works, and factory furnaces.

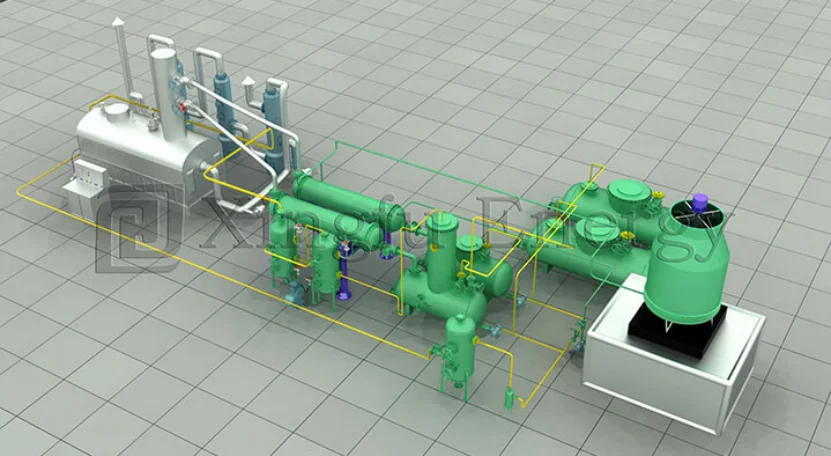

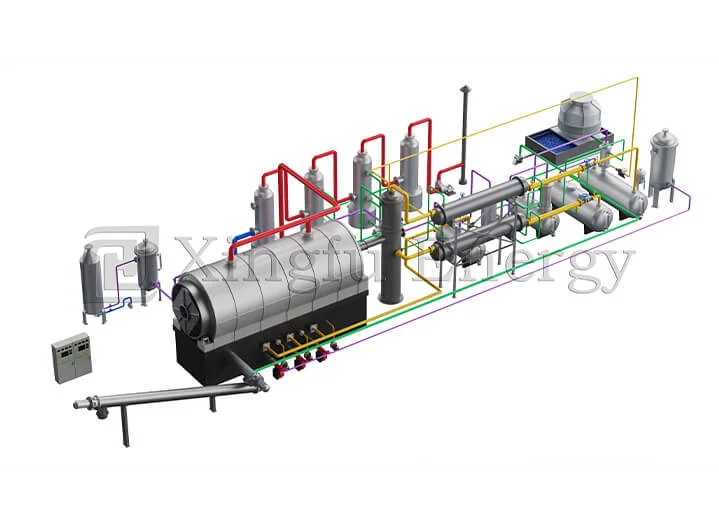

Pyrolysis oil is getting more use in heat and power setups thanks to its strong energy punch and speed. It can swap out usual fuels like coal and oil. This makes it a solid pick for trades aiming to shift to renewable energy. Plus, its flexibility in things like boilers and power stations adds to its charm. Take Qingdao Xingfu Energy’s pyrolysis systems: they use multi-step cooling loops to nab the most fuel oil. They hit a 40-45% recovery rate for waste tires.

The swelling global waste problem has sparked a need for smart fixes like pyrolysis tech. It turns tough-to-break-down waste like plastics and tires into useful stuff like pyrolysis oil. This not only tackles waste toss-out woes but also brings back resources. Governments everywhere are backing these methods with perks and rules to push circular economies.

Pyrolysis oil works as a sharp fuel for boilers and power stations due to its big heat value. Using it cuts reliance on usual fossil fuels while keeping energy steady. Qingdao Xingfu Energy’s fully automatic systems make running them a breeze with high output. They need just 2-3 workers. Tech like sealed high-heat feeding lifts their efficiency even more.

The sea trade is hunting for swaps to regular marine fuels because of tight green rules on sulfur fumes. Pyrolysis oil offers a low-sulfur pick that meets global sea standards. Its fit with different engine types makes it a strong bet for wide use in sea travel.

Pyrolysis oil also plays a big part in making bitumen for roads and zinc oxide for factories. These uses show its range—not just as fuel but as a base for various trade goods.

The Asia Pacific area is stepping up as a top spot for pyrolysis oil growth thanks to fast factory and city growth. Places like China and India are taking up pyrolysis tech big-time to handle their rising waste piles while meeting energy needs. Qingdao Xingfu Energy, based in Qingdao city, Shandong province, crafts advanced pyrolysis systems shaped for local demands.

Europe keeps leading green efforts with clean-tech plans to cut greenhouse gases. The European Union’s rules pushing renewable energy have sped up pyrolysis tech use across its lands. This area’s aim to hit carbon neutrality by 2050 makes it a key player in growing the pyrolysis oil market.

New markets in Africa and South America are starting to see pyrolysis tech’s worth for tackling waste woes while making cash from waste goods. These spots are putting money into building setups and rule frameworks that back smart fixes like pyrolysis oil making.

Pyrolysis oil plays a hefty role in hitting carbon-neutral aims by slashing greenhouse gas releases. It’s pulled from waste like used tires and plastics. It burns cleaner than regular fossil fuels. Turning waste into pyrolysis oil keeps it from burning up or piling in dumps where it’d spit out bad stuff. This fits global pushes to ease planet harm and fight climate shifts. The fuel oil from pyrolysis can power diesel engines, heat ovens, metal works, and factory furnaces. Swapping old fuels with pyrolysis oil helps trades build a greener tomorrow.

The growing lean on renewable energy is fueling pyrolysis oil demand. Unlike fossil fuels, which run out and hurt nature, pyrolysis oil comes from waste you can renew. This shift cuts reliance on limited energy picks. It also backs the circular economy by reusing tossed-out stuff. Pyrolysis systems from firms like Qingdao Xingfu Energy max out recovery rates. They ensure waste gets used well with little green harm.

Pyrolysis tech tackles the urgent waste handling issue by turning tough-to-break materials into worthy goods like fuel oil and carbon black. This fresh approach shrinks waste heaps in dumps or seas. It softens their bad effects on nature spots. Governments worldwide see pyrolysis tech’s power to back green waste habits. They’re rolling out rules to nudge its use.

Weaving pyrolysis oil making into plastic recycling loops opens a bright path for tackling plastic mess. It turns mixed or dirty plastics—hard to recycle the usual way—into high-worth pyrolysis oil. This tech pairs well with current recycling tricks. Qingdao Xingfu Energy’s fully automatic plastic pyrolysis plants hit a 60-85% recovery rate. They show sharp skill in handling all sorts of plastic waste. As planet-wide worry about plastic junk grows, demand for advanced fixes like pyrolysis should climb.

Beyond fuel, pyrolysis oil has room to make high-worth chemicals that feed various trades. Think solvents, resins, and special chemicals for factory jobs. Spreading out its uses lifts its market pull. It also sparks fresh ideas in the chemical world.

As trades worldwide chase green goals, pyrolysis oil is set to shake up global factory ways. Its fit across many fields—from energy making to chemical crafting—puts it as a top pick in the shift to greener trade habits. Using advanced tech and more cash for research will boost pyrolysis systems’ speed and reach.

It’s a liquid fuel got from heat-breaking organic stuff like plastics or tires at high heat without oxygen.

It cuts greenhouse gas releases by burning cleaner than fossil fuels. It also reuses waste that’d otherwise dirty things up.

Yes, it can swap in for regular fuels in boilers, power stations, sea engines, and other factory uses.

Fields in energy making, chemical crafting, sea travel, and waste handling can gain big from it.

For more details on custom fixes from Qingdao Xingfu Energy Equipment Co., Ltd., feel free to reach out via their official lines listed above!