● Oil yield reaches to 90%, conversion rate to 100%

● Unique heat system by hot air, avoid high temperature heat reactor directly. Equipment Would be safer and longer working life.

● Research and develop catalyst aiming at fuel oil, to make a better performance at catalyst.

● Equipment processing use full automatic submerged arc welding, X-ray flaw detection, to ensure excellent quality.

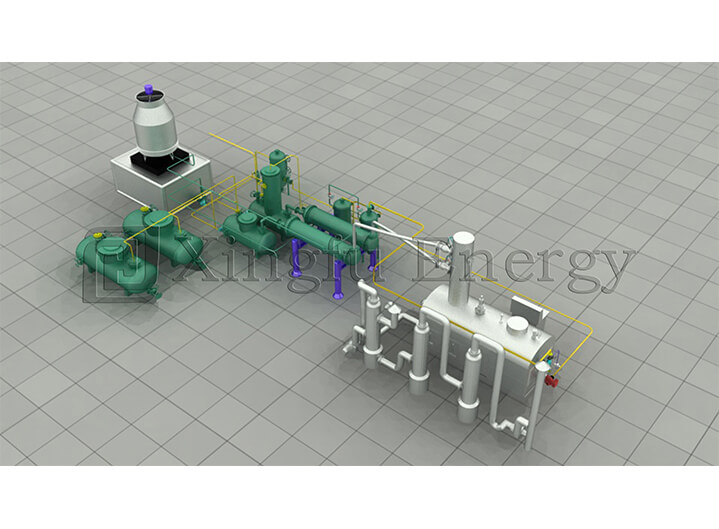

1.Technological Process

Raw oil after dewatering process goes into reactor. Heating, gasifying and cooling to get petrol and diesel component.

After heating and gasifying, Petrol gas expels from top outlet of catalyze tower, and goes into petrol storage tank after cooling through condenser. Then inject petrol into another big storage tank.

After heating and gasifying, Diesel gas expels from top outlet of catalyze tower, and goes into diesel storage tank after cooling through condenser. Then inject diesel into another big storage tank.

Distilled diesel after treatment by oil reconcile tank, will becoming fuel oil with high quality.

A little of flammable gas go through medium tank and into exhaust gas treatment equipment to be processed. And then go through water deal into furnace.

2.Main Performance Parameter

| Item | Type | XFZL–10 |

| Capacity | 10T | |

| Working temp. | ≤650° | |

| Fuel | Fuel oil, Natural gas, Liquefied gas | |

| Heating way | Circulating hot air heating | |

| Distillation material | Plastic oil, tyre oil, wasted oil and residual oil | |

| Working pressure | Normal pressure | |

| Consumption | 250 kg | |

| Size | 6600mm(L)×2500mm(W)×2850mm(H) | |

| Total power | 36 kw | |

| Power consumption | 15 kw/h | |

| Floor space | 19000 mm × 3600 mm | |

| Highest point of installation | 6000 mm | |

Remark: This parameter is just for reference. Size change caused by design improvement will not inform customers specially. Please refer to documents enclosed with products.

3.Product Recovery Rate

Petrol: 15-20%

Gas : 70-75%

Flammable gas: 2-5%

Residue: 10-18%